Day 2 :

Keynote Forum

Urs von Stockar

Swiss Federal Institute of Technology, Lausanne (EPFL), Switzerland

Keynote: Biothermodynamics: Bridging thermodynamics with biochemical Engineering

Time : 10:00-10:40

Biography:

Urs von Stockar has been professor of chemical and biochemical engineering since 1977 and has conducted research on gas-liquid mass transfer, integrated bioprocessing and biothermodynamics. Since 2007 he is honary (emeritus) professor at EPFL. He served as adjunct professor at Dublin City University from 2007 to 2014. He is a personal member of the Swiss Academy of Technical Sciences and is a member of their board. He was the Chairman of the European Federation of Biotechnology in 1996-97.

Abstract:

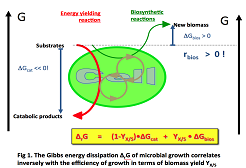

Thermodynamics has had an enormous impact on a very wide variety of fields, including chemical engineering. Systematic application of chemical thermodynamics to process technology is one of the reasons why petrochemical processes can often be developed with a bare minimum of experimental work. In biochemical engineering the state of matter is radically different. The need for experimental trials is so overwhelming in bioprocess development that more often than not extensive use is made of high-throughput experimental platforms. However, more systematic application of thermodynamics in bioprocess development might obviate a substantial fraction of this tedious experimental work. This presentation will offer an overview of biothermodynamics and the contributions it could make to different areas of biochemical engineering.

Biothermodynamics may be subdivided into 3 large areas according to the scale used to formalize the description of the biological system. The most fundamental level uses a system description at the molecular level, and thus concerns mainly biomolecules. It is the best-developed area of the three and has many practical applications such as DSP and biomolecule stability and activity. However, when studying the behavior of live cells it is more appropriate to adopt a coarser level and to describe the thermodynamics of whole metabolic pathways. This area was mainly developed for systems biology and has proven useful in metabolic engineering and synthetic biology. Finally, when dealing with live cultures the thermodynamic description often has to be even further simplified by treating whole cells as black boxes. This type of analysis has been shown to be able to approximately predict important culture performance parameters such as growth and product yields, and maximum specific growth rates. Gibbs energy analysis shows that the efficiency of microbial metabolism is fundamentally limited by maintenance requirements, like in the design of technical systems such as heat exchangers and distillation columns.

Keynote Forum

Christophe LEN

Sorbonne Université, France

Keynote: Bio-based chemistry in water: Future perspectives in catalysis

Time : 11:00-11:40

Biography:

Christophe Len received his Ph.D. from the University of Picardie-Jules Verne (UPJV) in Amiens (France) under the supervision of Professor P. Villa in the field of carbohydrate chemistry. In 2010, CL became full Professor at the University of Compiegne - UTC (France). The principle interests of Christophe Len are organic synthesis including the reactivity of biomass-derived molecules (glycerol, fatty acids, lignin, cellulose) for the formation of new chemical bonds. His scientific work has been published in around 137 original international publications and review articles, 3 chapters and 6 patents including publications in high profile journals.

Abstract:

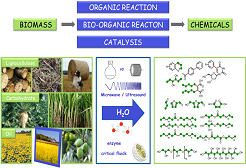

The design of environmentally friendly methodologies has been the driving force of scientists in recent years. In particular, the use of biomass-derived materials, green solvents and alternatives techniques has been investigated.

In this conference, several green chemistry approaches that target advanced synthesis and processes will be presented. These approaches include: (i) green synthesis of quinoline and phenanthroline derivatives in sole water using microwave irradiation and high temperature/pressure;(ii) production of furfural from D-xylose, xylane and hemicellulose via homogeneous and heterogeneous catalysis using microwave irradiation and high temperature/pressure; (iii) conventional micellar catalysis and magic photochromic micellar catalysis.

Conception, synthesis and physico-chemical properties will be detailed.

- Session 1: Petroleum Engineering

Location: Sunset 2

Chair

Amarjit Bakshi

Refining Hydrocarbon Technologies LLC, USA

Session Introduction

Amarjit Bakshi

Refining Hydrocarbon Technologies LLC, USA

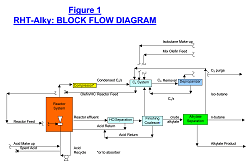

Title: Change refinery gasoline economics by breakthrough smart technologies: RHT- Alkylation and RHT-Iso-octene and Iso-octane

Time : 11:40-12:05

Biography:

Over 40 year’s experience in Engineering/ Consulting Management at senior level in Process Engineering, Technology, Business Development, Licensing, Acquisitions, Alliances and Project Management and Engineering, Operations Management and Process Engineering. Provided proven leadership and vision with broader perspectives and able to manage multiple tasks and personnel on mega projects.

Patents provide refiners and petrochemical plants innovations to enhance the performance of the units. Worked in all EU countries including UK, Germany, The Netherland. Major developments in Oil and gas business, downstream and petrochemicals technology, Catalysts, international alliance, licensing & contract negotiation, technology marketing, new technology commercial launch, partner relations.

Dr Amarjit Bakshi has a Ph.D and also undergraduate degree both in Chemical Engineering from University of Surrey, Guildford, UK

Abstract:

Advances in Alkylation Technology: With The invent of RHT-Alkylation, sulfuric acid alkylation process configuration and equipment, provides multiple paradigm shifts and breakthroughs in the technology but keeping same reaction chemistry. The breakthroughs reduce the Capex and Opex in region of 40 to 50% compared to convential technology; this is not just improvements but major paradigm shift. The process uses a unique eductor-mixing device, which reduce the costs and maintenance requirements on stream factor with simple equipment. The unit uses classical coalescers for separating the acid and hydrocarbon from the contactor/reactor effluent, making it a dry process that simplifies the process by reducing equipment items, corrosion and cost. Additionally major breakthrough is in absorbing the auto refrigeration vapors in reactor effluent. This reduce the requirement for compressor saving 20 % Capex and 50 % of power requirements and operating costs. These are major benefits to the refining industry and should be embraced by the industry to make the competitiveness of the unit. RHT-Isooctene/iso-octane process provides major economics advantages with simple and smart configuration which enhances the yield and reduces the equipment sizes and utilities. Advances simplify the technology and provide economy of scale.

Mohammad A. AlKazimi

Kuwait Oil Company, Kuwait

Title: How can augmented reality change the future of the oil and gas Industry

Time : 12:05-12:30

Biography:

Dr. Mohammad A. AlKazimi is a Senior Reliability and Equipment Support Engineer at Kuwait Oil Company in Kuwait. He holds a Bachelor degree in Mechanical Engineering and a Masters degree in Industrial Engineering; both earned at the University of Toledo in Ohio, United States. As part of professional development program by the oil sector in Kuwait, he was one of the first of employees to be selected to peruse his higher degree. He joined the petroleum engineering program in Missouri University of Science and Technology. During his course of studies, he earned his Masters degree in Petroleum Engineering, as well as certificates in Safety Engineering, Leadership in Engineering Organizations, and Project Management, respectively. Dr. AlKazimi holds a PhD in Petroleum Engineering with focus area in Risk Assessment and Mitigation in the Petroleum Industry.

Abstract:

The concept of augmented reality is not new, yet, did get its fair share of success not until recently. In the summer of 2016, Pokémon go took over the world by literally moving people off of their couches and into the street and neighbourhood to capture virtual creatures via their mobile devices.

Although different industries have been implementing augmented reality as part of their business such technology into their business, yet the oil and gas industry remains well shy from considering it for a try-out.

This presentation addressed how augmented reality can be a game changer in the oil and gas industry, especially in knowledge transfer, and technical training of the newly joined engineers, operators, and technicians, respectively. In fact, and via the usage of handheld devices, site maintenance and operations can instantly view the repair manuals or any related information, such as operating historical data, and any related information. Operator, on the other hand, can survey their equipment and generate service requests in case of any abnormalities in performance. Applying advanced technology into our industry shall revolutionize the work environment and creates new levels of competition in quality of workmanship.

Ali Shaeri

The National Iranian Oil Engineering & Construction Co., Iran

Title: Optimization of delay coker unit by using of artificial neural network

Time : 12:30-12:45

Biography:

Ali Shaeri has a PhD in Process Design Engineer. He is expert in the Refinery’s Process Units Simulation, Process Equipment Design, and Refinery Units Operation. He is teaching related courses at the university as well. On the other hand, He is expert in the optimization, new method of mini-refinery design and related pilot plant design additionally. He is working in the National Iranian Oil Engineering & Construction Co. from 11 years. He obtained B.S. degree in Process Design Engineering in 2002, M.Sc. degree in Process Design Engineering in 2006 and PhD degree in Process Design Engineering in 2016.Since then he joined Process Specialty Committee and permanent member of Iranian Petroleum Standard from 2007 to present. He is the first designer of Mini Refinery in Iran and head of Process Department for Petroleum Desalting Project. He has to his credit more than 10 Technical Reports and proposals related to Process Design, as well as, 30 publications including papers in referred journals, books and conferences papers.

Abstract:

A Feed forward and multilayer Perceptron Artificial Neural Network (ANN) with back propagation algorithm was applied for optimization of Delayed Coking Unit (DCU). To this aim, one year of operating conditions were gathered from Distributed Control System (DCS) and laboratory data. Then all data were evaluated by experienced operators to determine the most effective operating condition. Conradson Carbon Residue (CCR), asphaltenes content and Feed API were selected for input of the ANN and the output was set to be maximum products yield. The inputs of neural network data are distributed for training, validation and testing sets in 60%, 20% and 20% ratios, respectively. A three-layer ANN was adopted to predict products yield in terms of aforementioned inputs. To find the best fitted ANN structure, several structures (around 1576) were examined. Here, a total of four combinations of transfer functions were tested against various training functions available in the MATLAB software. Only the random order incremental training with learning functions (TRAINR) and the Levenberg–Marquardt (TRAINLM) training functions were found to predict significantly accurate results. It was found out that the best structure had 4, 6 and 1 neuron for the first, second and third layer, respectively. Furthermore, logsig, logsig and purelin were found the best transfer function for first, second and third layer. The best model was extracted and the obtained data were applied to the live DCU with the capacity of 90000 bbl d-1. Transfer functions are generally assigned to a network layer to first process the input signal, followed by the calculation of suitable weight for the output signal such that the relations of the data set can be identified. According to many structures which can be used in ANN, an optimization method using correlation coefficient (R) was recommended to optimize the number of neurons and transfer function types. The results showed that the selected model could be exactly matched with the DCU.

Ali Shaeri

The National Iranian Oil Engineering & Construction Co., Iran

Title: Increasing research octane number in a catalytic reforming unit by employing artificial neural network

Time : 12:45-13:00

Biography:

Ali Shaeri has a PhD in Process Design Engineer. He is expert in the Refinery’s Process Units Simulation, Process Equipment Design, and Refinery Units Operation. He is teaching related courses at the university as well. On the other hand, He is expert in the optimization, new method of mini-refinery design and related pilot plant design additionally. He is working in the National Iranian Oil Engineering & Construction Co. from 11 years. He obtained B.S. degree in Process Design Engineering in 2002, M.Sc. degree in Process Design Engineering in 2006 and PhD degree in Process Design Engineering in 2016.Since then he joined Process Specialty Committee and permanent member of Iranian Petroleum Standard from 2007 to present. He is the first designer of Mini Refinery in Iran and head of Process Department for Petroleum Desalting Project. He has to his credit more than 10 Technical Reports and proposals related to Process Design, as well as, 30 publications including papers in referred journals, books and conferences papers.

Abstract:

Detailed operating condition were gathered from a live CCR unit (Lab. And DCS) for two years. The most significant parameters were selected by both simulation and experience. To increase RON, ANFIS models were designed and applied obtained results to the live CCR unit with the capacity of 30000 bbl day-1. The R2 and MSE of the proposed model were 0.92583 and 0.1424, respectively. It was found in the optimum operation conditions, the value of reformate product was 25714 bbl day-1.Obtained data from ANFIS for Feed final boiling point (FBP) , Recycle gas flow rate (RGF) , Reactor inlet temperature (RIT) , Coke percentage on catalyst (CPC), Catalyst circulation and H2 to HC mole ratio(H2/HC) were 165C,24.2tonhr-1,527C,2.42wt%,987.24kghr-1 and 2.82, respectively .Applying the ANFIS data resulted in an increase of RON amount, from 99 to 99.7, which can be addressed significant in terms of the unit economy. In addition, it was observed that about 640bblday-1 saved in the gasoline pool of the refinery.

Ali Shaeri

The National Iranian Oil Engineering & Construction Co., Iran

Title: Increasing research octane number in a catalytic reforming unit by employing artificial neural network

Biography:

Ali Shaeri has a PhD in Process Design Engineer. He is expert in the Refinery’s Process Units Simulation, Process Equipment Design, and Refinery Units Operation. He is teaching related courses at the university as well. On the other hand, He is expert in the optimization, new method of mini-refinery design and related pilot plant design additionally. He is working in the National Iranian Oil Engineering & Construction Co. from 11 years. He obtained B.S. degree in Process Design Engineering in 2002, M.Sc. degree in Process Design Engineering in 2006 and PhD degree in Process Design Engineering in 2016.Since then he joined Process Specialty Committee and permanent member of Iranian Petroleum Standard from 2007 to present. He is the first designer of Mini Refinery in Iran and head of Process Department for Petroleum Desalting Project. He has to his credit more than 10 Technical Reports and proposals related to Process Design, as well as, 30 publications including papers in referred journals, books and conferences papers.

Abstract:

Detailed operating condition were gathered from a live CCR unit (Lab. And DCS) for two years. The most significant parameters were selected by both simulation and experience. To increase RON, ANFIS models were designed and applied obtained results to the live CCR unit with the capacity of 30000 bbl day-1. The R2 and MSE of the proposed model were 0.92583 and 0.1424, respectively. It was found in the optimum operation conditions, the value of reformate product was 25714 bbl day-1.Obtained data from ANFIS for Feed final boiling point (FBP) , Recycle gas flow rate (RGF) , Reactor inlet temperature (RIT) , Coke percentage on catalyst (CPC), Catalyst circulation and H2 to HC mole ratio(H2/HC) were 165C,24.2tonhr-1,527C,2.42wt%,987.24kghr-1 and 2.82, respectively .Applying the ANFIS data resulted in an increase of RON amount, from 99 to 99.7, which can be addressed significant in terms of the unit economy. In addition, it was observed that about 640bblday-1 saved in the gasoline pool of the refinery.

- Session 2: Biofuels | Chemical Reaction Engineering | Transport Phenomenon| Safety Methods

Location: Sunset 2

Chair

Emad Alhseinat

Khalifa University

Session Introduction

Valentina Busini

Politecnico di Milano, Italy

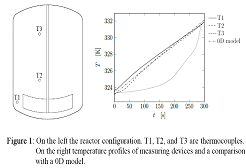

Title: Temperature sensors position in chemical reactors: The use of CFD

Time : 14:00-14:25

Biography:

Valentina Busini has her expertise in safety engineering and bioengineering. In particular, with regard to industrial safety, she usually works on the analysis of the consequences of industrial events related to emerging risks, such as the CFD modeling of heavy gas dispersion in complex environments, and the definition of methodologies for the evaluation of industrial accidents triggered by natural events (the so-called NaTech events). As far as bioengineering is concerned, she has focused on the interactions between materials and biomolecules, both for biocompatibility studies and for the development of protein separation processes.

Abstract:

Statement of the Problem: Runaway reactions have always been a serious issue for the chemical industry. Failures that may lead to this type of accident may be different: block of the impeller, loss of the reactor temperature control, error in the loading of reagents. The rapid detection of this phenomena is crucial. One of the most widely used preventive systems is the so-called early warning system, which allows to give an early warning at the beginning of the fugitive reaction. Due to non-homogeneity of the temperature inside the reactor, the positioning of the sensors is of crucial importance. In fact, an incorrect localization of the temperature probe could lead to a false alarm, which would undermine the early warning system. The objective of this work is the computational fluid dynamic (CFD) simulation of different failure scenarios, in order to determine the best location of the temperature sensors. Methodology & Theoretical Orientation: For this work a semi-batch reactor was used to simulate an accident in a pilot scale reactor. An impeller fault and a reagent loading error has been investigated in CFD using a new kinetic model for liquid reactions, implemented in ANSYS Fluent. Findings: Differently from what is present in the literature, CFD results show that depending on the incident considered, the best position for the thermocouple varies within the reactor. For the impeller fault the best position is in the upper region of the reactor, while for the loading error accident the best position is always in the proximity of the reagent mass. Conclusion & Significance: The simulations performed show the usefulness of CFD in analyzing these kind of problems and that there is no unique positioning of thermocouples which would be optimal to early-detect every runaway scenario. Here rises the importance of redundant measurements in a reactor.

Lali Gurchumelia

TSU Rafael Agladze Institute of Inorganic Chemistry and Electrochemistry, Georgia

Title: New types, halogen-free, eco-safe, inexpensive fire-extinguishing and fire- protective materials

Time : 14:25-14:50

Biography:

Lali Gurchumelia, Chemist, Doctor of Technical Sciences, works at TSU Rafael Agladze Institute of Inorganic Chemistry and Electrochemistry (Georgia). Scope of scientific interests: chemical science, chemical engineering, ecological engineering, ecological biotechnology. She has 55 publications, including in the impact factor Journals -10. The last 10 years she has participated in 5 scientific grants. Currently she is a manager of the grant # 216770 - “ New type fire-extinguishing powders and foam-suspensions based on local mineral raw materials “ funded by the National Science Foundation.She has also participated in many international conferences and congresses: Nürnberg, Germany; Toledo, Spain; New Forest, UK; Montreal, Canada; Istanbul, Turkey; Elenite Holiday Village, Bulgaria; Yerevan-Vanadzor; Tbilisi, Georgia and Ureki, Georgia. I have many years of experience in the study and evaluation of fire–extinguishing and fire- protective materials.

Abstract:

Fires are unsolved problems of world civilization. No less dangerous are the cases of population chocking and poisoning by fire, which is caused, mainly, by combustion products as well as by toxicity of using safety precautions. Therefore, the world faces the problem of fire localization, liquidation and development of such safety precautions, which will provide inhibition of burning of matter in the zone of inflammation and decrease of toxic materials emission. The use of fire-extinguishing and fire-protective means, occur topical among the mentioned measures. Unfortunately, the statistics confirms, that traditional fire-extinguishing and fire-protective materials, are sufficiently expensive, not universal, neither eco-safe and less efficient. Therefore, at present one of the most important problems is the elaboration of non-halogen, eco-safe fire-extinguishing and fire-protective materials.

In our work we describe the ways of development of technology for production of novel, halogen-free, eco-safe, highly efficient, universal fire-extinguishing powders based on local mineral raw materials and elaboration of new types, eco-safe fire-protective materials on the basis of such fire-extinguishing powders. The technology for production of these materials differs from the serial production technology. Fire-extinguishing powders we made by mechanical blending of local mineral raw materials, do not require modification with expensive, halogen-inclusive hydrofobizative additives, what makes the extinguishing materials far cheaper than imported analogues. Experimental data confirm that such powders are characterized by high inhibition properties and fire-extinguishing ability. Here it should be noted, that obtained powders similarly to inert flame retardants, don’t participate in the process of polymer preparation, and in contrast to them are characterized by high operating properties. Therefore, fire-extinguishing powders of our preparation in fire-protective materials are functioning, as efficient flame retardants.

Thus, fire-protective materials are manufactured only by mechanical mixing of binders- Polyurethane resins and fillers- High-dispersed fire-extinguishing powders of our preparation, does not need addition of expensive flame retardants. Therefore such fire-protective materials are eco-safe, very effective and far cheaper than imported analogues.

P. S. T. Sai

Indian Institute of Technology Madras, India

Title: Modeling and simulation of coal gasification in internally circulating fluidized bed

Time : 14:50-15:15

Biography:

P. S. T. Sai is a professor in Chemical Engineering at Indian Institute of Technology Madras. He has been actively involved in teaching and research for the past 32 years. His research interests include fluidization, reaction engineering and air pollution control. He has published over 80 research papers. His paper entitled “Esterification of ethanol with sulfuric acid: A kinetic study” was awarded as the best paper published in The Canadian Journal of Chemical Engineering in 2001. He also received Chemical Weekly Award, IIChE NRC Award and. Kuloor Memorial Award in 2012. He has handled many industrial projects and one of them is development of an equipment for simultaneous removal of particulates and SO2 from effluent gaseous streams.

Abstract:

Coal gasification is one of the best ways to convert the char into the synthesis gas. This process has proved to be very effective in Internally Circulating Fluidized Bed (ICFB) gasifier. In ICFB, there occurs gas bypassing from draught to annulus region and vice versa. In the present work, the effects of gas bypassing through the orifices on product gas compositions in both annulus and draught tube is studied following the modeling reported in literature.

The same modeling is applied to a coal of inferior quality and the conversion and product gas compositions at different temperatures and the effects of various parameters are studied. The number of circulations a particle should undergo, total gas yield and solid circulation rate inside the reactor is studied at different temperatures for different conversion levels. In addition, the effects of coal feed rate, particle size, and O2 to coal and H2O to coal mass ratio is studied on number of circulations, total gas yield and solid circulation rate.

The optimum operating conditions are also obtained to achieve a specified conversion with minimum number of circulations and maximum gas yield per kg of coal per pass through sequential optimization. For a mixture of particle of different sizes, the conversion and product gas composition in annulus region are studied and compared with uniform size particles. The product gas composition depends strongly on operating parameters such as O2/coal and H2O/coal mass ratio and gas bypassing values through the orifice.

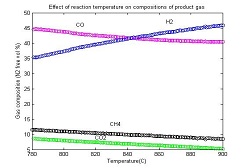

Figure 1: Composition of product gas in annulus region at different temperatures

Irina V. Deliy

Novosibirsk National Research University, Russia

Title: The performance of dual-bed system of MoS2/Al2O3 and Co-MoS2/Al2O3 catalysts in ULSD production from the mixture of rapeseed oil and SRGO

Time : 15:15-15:40

Biography:

Irina Deliy was graduated from Novosibirsk State University (2002) and completed her Ph.D. from Boreskov Institute of Catalysis, Novosibirsk, Russia (2009). She is a senior researcher in Group of Hydrogenation processes at the Boreskov Institute of Catalysis and a researcher in Novosibirsk National Research University, Russia. The main research topic is heterogeneous catalysis applied to renewable materials selective transformations. The main research topic is heterogeneous catalysis applied to renewable materials selective transformations. Research activity has been mainly focused on the development of heterogeneous sulfide and phosphide-based catalysts for the upgrading of renewable sources, such as vegetable oils and pyrolysis oil. Her scientific activity is summed up in17 scientific papers and 4 patents.

Abstract:

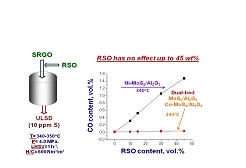

The critical challenge in the developing of the energy-efficient co-processing of triglyceride-based feedstock with straight–run gas oil (SRGO) for ULSD (ultra-low sulfur diesel) production is the elucidation of peculiarities of sulfide catalyst’s behaviour depending on their chemical composition. It is known, that the triglycerides conversion over sulfide Co(Ni)Mo/Al2O3 catalysts proceeds through the deoxygenation (with the water formation) or via decarbonylation (with COx production) pathways. But COx production is highly undesirable, because of ecological and technological reasons. In our work dual-bed catalytic system is proposed for the co-processing of rapeseed oil (RSO) – SRGO mixture into ULSD. The Mo/Al2O3 catalyst is used in the front layer to provide RSO conversion without considerable COx formation, the SRGO hydrotreating proceeds over traditional CoMo/Al2O3 catalysts. CoMo/Al2O3, NiMo/Al2O3 and dual-bed system (MoS2/Al2O3 and Co-MoS2/Al2O3 catalysts) were compared in the hydrotreating of blended feedstocks (up to 45% of RSO) using full-sized commercial granules and trickle-bed reactor. Total S, N, O contents and quality of produced fuels was checked using the corresponding ASTM methods. Characterization of the catalysts after reaction with TEM confirmed the formation of highly dispersed MoS2, CoMoS, and NiMoS nanoparticles. It was observed, that over NiMoS/Al2O3 catalyst ULSD can be produced from SRGO and RSO-SRGO blends at the same conditions (at 4.0 MPa, 340oC, LHSV - 1,5 h-1, H2/C- 600), while the sufficient increase of temperature is needed if the CoMoS/Al2O3 catalyst is used. In the case of the dual-bed system, RSO content has only minor effect on the catalyst efficiency in hydrotreating reaction, confirming that the decrease of HDS activity of CoMoS/Al2O3 catalyst in presence of RSO is due to CO inhibition. The use of dual bed system increase the products yield prevents COx formation and avoid the necessity of costly and energy-intensive purification of recycle hydrogen in co-processing of RSO-SRGO mixtures.

Acknowledgement: The work was supported by the Ministry of Education and Science of the Russian Federation, unique identificator RFMEFI57517X0128.

Figure 1: Effect of the rapeseed oil content on CO production during co-processing of rapeseed oil-SRGO mixture into ULSD over Ni-MoS2/Al2O3 and dual-bed system (MoS2/Al2O3 and Co-MoS2/Al2O3 catalysts).

Reza Marandi

National Petrochemical Company, Research and Technology,Iran

Title: Investigating the effects of inlet gas velocity on the operation of multi-zone circulating reactors: A CFD study

Time : 15:40-16:05

Biography:

Reza Marandi is Researcher in the Department of Polymer at the National Petrochemical Company, Research and Technology, Tehran, Iran. He had also worked as a research and development engineer at Tabriz Petrochemical Company. He obtained his Phd from Univercity Technology-Malaysia(UTM).

Abstract:

A 3-D model based on computational fluid dynamics was developed for studying the effects of inlet gas velocity on the operation of multi-zone circulating reactors (MZCRs) from a hydrodynamic viewpoint. The system was modeled by the two fluid model (TFM) based on the kinetic theory of granular flow (KTGF). The re-normalization group (RNG) k-ε model was applied for implementing the turbulency. Effect of inlet gas velocity on overriding parameters, such as pressure drop and solid volume fraction, was studied. The results showed a limitation in both increasing and decreasing the inlet gas velocity. Therefore, operating at a proper range of inlet gas velocity is recommended for MZCRs.

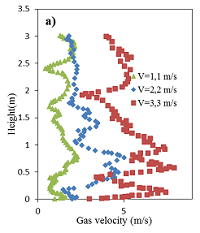

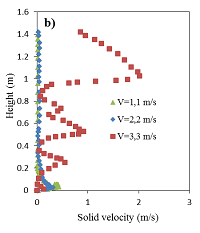

Figure Gas velocity along axis of a) riser and b) downer at different inlet gas velocities